Styrene-butadiene rubber 1502

Specifications

| Item | Superior product | First class product | Qualified product | Test method | ||||

| Volatile components % | ≤ 0.60 | ≤ 0.75 | ≤ 0.90 | GB/T 16737-1997 | ||||

| Ash % | ≤0.50 | GB/T 4498-1997 A | ||||||

| Organic acid content % | 4.50—6.75 | GB/T 8657-2000 A | ||||||

| Soap % | ≤ 0.50 | |||||||

| Combined with phenylacetic acid % | 22.5—24.5 | GB/T 8658-1998 | ||||||

| Raw rubber Viscosity ML, (1+4)100℃ | 45-55 | 44-56 | GB/T 1232.1-2000 | |||||

| Mooney viscosity ML, (1+4)100℃ | ≤93 | GB/T 1232.1-2000 | ||||||

| 300 constant tensile stress 25 min 145℃/ (MPa) 35 min 50 min | 15.5±2.0 | 15.5±2.5 | GB/T 8656-1998 A | |||||

| 20.6±2.0 | 20.56±2.5 | |||||||

| 21.5±2.0 | 21.5±2.5 | |||||||

| Tensile strength(145℃,35min), MPa | ≥25.5 | ≥24.5 | ||||||

| Tensile Elongation at Break(145℃,35min), % | ≥ 340 | ≥ 330 | ||||||

Packing & Storage

| Packing | Packed in polyethylene composite bags with lining, the net weight of each package of rubber is 35 kg | |||||||

| Storage | Stored in a warehouse at room temperature, with clean ventilation and dryness, it is strictly forbidden to be folded outdoors and in direct sunlight; | |||||||

| Transportation | Measures should be taken to keep it clean during transportation to prevent direct sunlight and rainwater from soaking, as well as to avoid damage to the packaging or mixing debris. | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Styrene-butadiene rubber SBR 1502 | |||||||

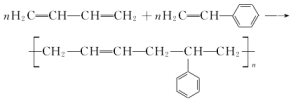

| Structure |  C12H14 C12H14 |

|||||||

| CAS No. | 9003-55-8 | Boiling Point (℃) | 145.2ºC at 760 mmHg | |||||

| Molecular Weight | 158.24 | Melting Point (℃) | -59ºC | |||||

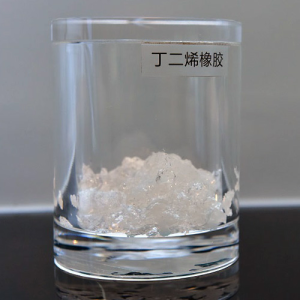

| Appearance | Milky white liquid with light blue gloss | Density | 1.04 g/mL at 25ºC | |||||

| HS Code | 4002119000 | Flash Point (ºF) | 31.1ºC | |||||

| Stability | Stable. Combustible. Incompatible with strong oxidizing agents. | LogP | 3.68800 | |||||

| RIDADR | NONH for all modes of transport | ||

| WGK Germany | 3 | ||

| RTECS | WL6478000 | ||

| Personal Protective Equipment | Eyeshields;Gloves;type N95 (US);type P1 (EN143) respirator filter | ||

| FIRST AID | PREVENTION | |

| Inhalation | If inhaled, move the patient to fresh air. If breathing is stopped, artificial respiration is performed..Consult a doctor. | No need to protect breathing. If you need to protect against dust damage, please use a type N95 (US) or type P1 (EN 143) dust mask. |

| Skin | Rinse with soap and plenty of water. Consult a doctor. | Protective gloves. |

| Eyes | Rinse your eyes with water as a precaution. | Please use equipment that has been tested and approved by official standards such as NIOSH (United States) or EN 166 (European Union) to protect your eyes. |

| Ingestion | Do not feed anything from the mouth of the unconscious person. Rinse your mouth with water..Consult a doctor. | Do not eat, drink, or smoke during work. Wash hands before eating. |

It is obtained by emulsifying and copolymer of butadiene and styrene.Rosin acid soap or fatty acid soap is used as an emulsifier, persulfate is used as a catalyst, and if necessary, a suitable molecular weight regulator and a suitable reaction speed regulator are added.The resulting product is liquid latex.

Frequently Asked Questions

Applications of Styrene-butadiene rubber 1502

Styrene-butadiene rubber (SBR) 1502 is a synthetic rubber compound that is widely used in various applications due to its desirable properties and cost-effectiveness. Here are some common applications of SBR 1502:

1. Tires: SBR 1502 is extensively used in tire manufacturing due to its excellent abrasion resistance, high elasticity, and good tensile strength. It helps improve the grip and durability of tires, making them suitable for various road conditions.

2. Footwear: SBR 1502 is used in the production of shoe soles, midsoles, and outsoles. Its flexibility, impact resistance, and slip resistance properties make it an ideal material for footwear, providing comfort and durability.

3. Conveyor belts: SBR 1502 is commonly used in the production of conveyor belts due to its high tensile strength and resistance to abrasion. It enables the belts to withstand heavy loads and repetitive impact, making it suitable for various industries such as mining, manufacturing, and logistics.

4. Seals and gaskets: SBR 1502 is employed in the manufacture of seals and gaskets due to its good compression set resistance and sealing properties. It provides an effective barrier against leaks and is commonly used in automotive, construction, and industrial applications.

5. Adhesives: SBR 1502 is used as a binder in adhesive formulations, including pressure-sensitive adhesives and hot melt adhesives. Its good tackiness and compatibility with various fillers and resins make it a popular choice in the adhesive industry.

6. Industrial rubber products: SBR 1502 is utilized in the production of various industrial rubber products such as hoses, belts, grommets, and O-rings. Its mechanical strength, resistance to chemicals, and low water absorption make it suitable for demanding industrial applications.

7. Construction materials: SBR 1502 is used in the construction industry for applications like roofing membranes, waterproofing systems, and expansion joints. Its flexibility, weather resistance, and ability to adhere to different substrates make it a preferred material in construction applications.

8. Consumer goods: SBR 1502 can be found in various consumer goods such as rubber bands, gloves, and inflatable products. Its elasticity, durability, and low cost make it an attractive option for these applications.

It’s worth noting that while SBR 1502 has many advantages, it may not be suitable for applications that require high heat resistance or exposure to oils and solvents. In such cases, other rubber compounds like nitrile rubber (NBR) or ethylene propylene diene monomer (EPDM) may be more appropriate.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.