Methyl tert-butyl ether

Specifications

| Item | Supperior product | First class product | Quality product | ||||

| Methyl tert-butyl ene content | ≤ 98.7 | ≤ 98.0 | ≤ 95.0 | ||||

| Methanol content,% (m/m) | ≤ 0.18 | ≤ 1.0 | / | ||||

| Carbon four,% () | ≤ 0.4 | ≤ 0.5 | / | ||||

| Dimerisobutylene content | ≤ 0.5 | / | / | ||||

Packing & Storage

| Packing | Small-opening steel drums; ordinary wooden boxes outside ampoules; ordinary wooden boxes outside threaded glass bottles, pressed glass bottles with iron caps, plastic bottles or metal barrels (cans). | |||||||

| Storage | Stored in a warehouse at room temperature, with clean ventilation and dryness, it is strictly forbidden to be folded outdoors and in direct sunlight; | |||||||

| Transportation | During transportation, the transportation vehicle should be equipped with corresponding varieties and quantities of fire-fighting equipment and leakage emergency treatment equipment | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

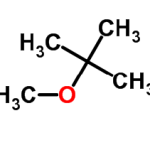

| Common Names | Methyl tert-butyl ether | |||||||

| Structure |  C5H12O C5H12O | |||||||

| CAS No. | 1634-04-4 | Boiling Point (℃) | 55.2±0.0 °C at 760 mmHg | |||||

| Molecular Weight | 88.148 | Melting Point (℃) | -110 °C | |||||

| Appearance | Colorless liquid with an ether-like odor. | Density | 0.8±0.1 g/cm3 | |||||

| HS Code | 2909199090 | Flash Point | -10.0±0.0 °C | |||||

| Water Solubility | 51 g/L (20 ºC) | Vapour Pressure | 251.3±0.1 mmHg at 25°C | |||||

| Safety Phrases | S9-S16-S24-S45-S36/37 | ||

| RIDADR | UN 2398 3/PG 2 | ||

| WGK Germany | 3 | ||

| Packaging Group | II | ||

| Hazard Class | 3 | ||

| FIRST AID | PREVENTION | |

| Inhalation | Quickly leave the scene to a place with fresh air.Keep the respiratory tract unobstructed.If you have difficulty breathing, give oxygen.If breathing stops, perform artificial respiration immediately.Seek medical attention. | If you come into contact with its vapor, wear a filter gas mask (half mask). |

| Skin | Take off contaminated clothing and rinse the skin thoroughly with soapy water and clear water. | Wear anti-static overalls. |

| Eyes | Lift the eyelids and rinse with flowing water or saline.Seek medical attention. | Wear chemical safety protective |

| Ingestion | Drink a sufficient amount of warm water to induce vomiting.Seek medical attention. | Do not eat, drink, or smoke during work. Wash hands before eating. |

Frequently Asked Questions

Applications of Methyl tert-butyl ether

Methyl tert-butyl ether (MTBE) is a chemical compound with various applications in different industries. Here are some common uses of MTBE:

1. Fuel Oxygenate: One of the primary applications of MTBE is as a fuel additive in gasoline. MTBE improves the octane rating of gasoline and enhances its combustion efficiency. It also acts as an oxygenate, helping to reduce air pollution by promoting complete combustion and reducing carbon monoxide emissions from vehicles.

2. Solvent: MTBE is used as a solvent in several industrial processes. It effectively dissolves various organic compounds, including fats, oils, resins, and polymers. It is commonly used to produce adhesives, coatings, inks, and cleaning agents.

3. Extractive Distillation: MTBE is utilized in extractive distillation processes to separate or purify different components of a mixture. It forms azeotropic mixtures with certain compounds, which allows for separating components with similar boiling points, such as the dehydration of alcohols or the separation of aromatic compounds.

4. Octane Enhancer: Besides its role as a fuel oxygenate, MTBE is employed as an octane enhancer in aviation fuels, racing fuels, and other high-performance applications. It improves the fuel’s resistance to knocking, enabling higher compression ratios and increased engine power output.

5. Chemical Intermediate: MTBE is a precursor or intermediate in producing other chemicals. It can be converted into tert-butyl alcohol (TBA) through hydrolysis, and further used to synthesize various chemicals, including isobutylene, methyl methacrylate, and tert-butyl hydroperoxide.

6. Laboratory Reagent: MTBE is used in laboratories as a reagent and solvent for certain chemical reactions. It is commonly employed in organic synthesis, extractions, and as a reaction medium due to its low boiling point, good solvating properties, and low toxicity.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.