Acrylic staple fiber

Specifications

| Item | Supperior product | First class product | Quality product | ||||||

| Linear density deviation rate,% | <2.22dtex ± | 6 | 8 | 12 | |||||

| 2.22dtex-11.11dtex ± | 8 | 10 | 14 | ||||||

| Breaking strength, cN/dtex | <2.22dtex | 3.3±0.5 | 3.3±0.6 | 3.3±0.8 | |||||

| 2.22tex, <3.33dtex | 2.7±0.5 | 2.7±0.6 | 2.7±0.8 | ||||||

| >3.33dtex, <6.67dtex | 2.5±0.5 | 2.5±0.6 | 2.5±0.8 | ||||||

| >6.67dtex, ≤11.11dtex | 2.1±0.6 | 2.1±0.8 | 2.1±1.0 | ||||||

| Elongation at break.% | <2.22dtex | 28±8 | 28±10 | 28±14 | |||||

| <2.22dtex,<6.67dtex | 36±10 | 36±12 | 36±14 | ||||||

| >6.67dtex, ≤11.11dtex | 46±10 | 46±12 | 46±14 | ||||||

| Defects, mg/100g | <2.22dtex ≥ | 15 | 20 | 100 | |||||

| <2.22dtex-11.11tex ≤ | 15 | 60 | 200 | ||||||

| Double-length, mg/100g | <2.22dtex ≥ | 40 | 60 | 600 | |||||

| <2.22dtex-11.11tex ≤ | 100 | 500 | 1500 | ||||||

| Number of curls | <2.22dtex ≥ | 40 | 35 | 25 | |||||

| 2.22tex, <3.33dtex ≥ | 32 | 28 | 25 | ||||||

| >3.33dtex, <6.67dtex ≥ | 28 | 25 | 20 | ||||||

| >6.67dtex, ≤11.11dtex ≥ | 22 | 20 | 16 | ||||||

| Length deviation rate,% | ≤76mm | 8 | 10 | 16 | |||||

| ≥89mm | 11 | 13 | 19 | ||||||

| Boiling Water Shrinkage | ≤ | 3 | 3 | 4 | |||||

| Color rate deviation,% | ± | 3 | 4 | 7 | |||||

Packing & Storage

| Packing | It is packed in composite plastic woven bags, with a single package quality of about 630kg; | |||||||

| Storage | Stored in a dry and ventilated warehouse and equipped with fire-fighting facilities; | |||||||

| Transportation | During transportation, it is necessary to prevent damage to the outer packaging and cause fiber pollution and avoid moisture. | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Acrylic Staple Fiber | |||||||

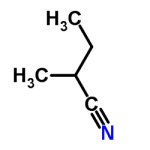

| Structure |  | |||||||

| CAS No. | 25014-41-9 | Boiling Point (℃) | 127.3±8.0 °C at 760 mmHg | |||||

| Molecular Weight | 83.132 | Melting Point (℃) | 317ºC | |||||

| Appearance | Fluffy and soft to the touch | Density | 0.8±0.1 g/cm3 | |||||

| LogP | 0.96 | Flash Point | 24.4±0.0 °C | |||||

| Water Solubility | Insoluble in water | Vapour Pressure | 11.2±0.2 mmHg at 25°C | |||||

| Safety Phrases | 24/25 | ||

| RIDADR | NONH for all modes of transport | ||

| WGK Germany | 3 | ||

| Personal Protective Equipment | Eyeshields;Gloves;type N95 (US);type P1 (EN143) respirator filter | ||

| RTECS | AT6977900 | ||

| FIRST AID | |

| Inhalation | If inhaled, move the patient to fresh air. If breathing stops, perform artificial respiration. |

| Skin | Rinse with soap and plenty of water. |

| Eyes | Rinse your eyes with water as a precaution. |

| Ingestion | Never feed anything through the mouth to the unconscious person. Rinse your mouth with water. |

The temperature is 80, which is mechanically curled by an extrusion curling machine, and then dried under 80 by a secondary oiling and curtain dryer to make the tow water content <2%, and then sent to cut off. The cutting length can be from 38 mm to 150mm as needed. After cutting off, the tow is sent to the hydraulic baler for packing. The 12% to 27% ZnCI2 from the spinning bath is mixed with a dilute solvent, first through a filter to remove impurities, and then into a thin film evaporator to remove unreacted monomers.The separated monomer comes out of the gas phase and is distilled and sent to the polymerization process for reuse.The liquid phase increased by 35% to 40% ZnCI2, and was transferred to the evaporator for further concentration, and finally 55% to 60% ZnCI2 agent was prepared. The crude solvent can be adjusted to PH 5 with NaOH, and H2O2 is added to oxidize and precipitate heavy metals (mainly iron), which are removed by filtration.

Frequently Asked Questions

Advantages of Acrylic Staple Fiber

Acrylic staple fiber, also known as acrylic fiber, is a synthetic fiber made from polymers derived from petroleum. It offers several advantages in various applications. Here are some of the advantages of acrylic staple fiber:

1. Softness and Comfort: Acrylic staple fiber has a soft and wool-like feel, making it comfortable to wear. It provides warmth and insulation while remaining lightweight.

2. Moisture Wicking: Acrylic fibers have excellent moisture-wicking properties. They can absorb moisture and transport it away from the body, keeping the wearer dry and comfortable.

3. Colorfastness: Acrylic staple fiber has good colorfastness, meaning it retains its color even after repeated washing and exposure to sunlight. It is less prone to fading compared to natural fibers like cotton.

4. Durability: Acrylic staple fiber is highly durable and resistant to wear and tear. It has good resistance to chemicals, sunlight, and abrasion, making it suitable for various applications that require long-lasting performance.

5. Wrinkle Resistance: Acrylic fibers have inherent wrinkle resistance, which means they tend to retain their shape and appearance even after prolonged use or washing. This makes acrylic garments easier to care for and maintain.

6. Resistance to Moth and Mildew: Unlike natural fibers, acrylic staple fiber is not susceptible to damage from moths or mildew. This makes it a suitable choice for applications where protection against these pests is necessary, such as carpets and upholstery.

7. Easy Care: Acrylic fibers are relatively easy to care for. They are machine washable, quick-drying, and often do not require ironing. This makes them convenient for everyday use and reduces the need for special maintenance.

8. Versatility: Acrylic staple fiber can be easily blended with other fibers, such as wool or cotton, to enhance its properties. This versatility allows for a wide range of applications, including clothing, blankets, carpets, upholstery, and industrial textiles.

9. Cost-Effective: Acrylic staple fiber is generally more affordable compared to natural fibers like wool. It provides a cost-effective alternative without compromising on performance and aesthetic qualities.

It’s important to note that while acrylic staple fiber offers many advantages, it also has some limitations. For example, it is less breathable compared to natural fibers, and it may have a lower environmental sustainability profile due to its petroleum-based origin. However, advancements in technology have led to the development of more eco-friendly and sustainable versions of acrylic fibers.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.