Terephthalic acid(PTA)

Specifications

| Item | Index | |||

| Superior product | First class product | |||

| Appearance | White powder | 99.90 | ||

| Acid value, mgKOH/g | 675±2 | 675±2 | ||

| p-carboxybenzaldehyde, mg/kg ≤ | 25 | 25 | ||

| Ash content, mg/kg ≤ | 8 | 15 | ||

| Total metal (molybdenum, chromium, nickel, cobalt, manganese, titanium, iron), mg/kg ≤ | 5 | 10 | ||

| Iron, mg/kg ≤ | 1 | 2 | ||

| Moisture, % (mass fraction) ≤ | 0.2 | 0.5 | ||

| 5g/100mL DMF chromaticity, platinum-cobalt color number ≤ | 10 | 10 | ||

| P-methylbenzoic acid, mg/kg ≤ | 150 | 200 | ||

Packing & Storage

| Packing | The bagged products are packed with inner lining film, and the net weight of each bag is 1000±2 kg. Stainless steel tank cars can also be used for transportation. | |||||||

| Storage | Store in a cool and ventilated warehouse. Keep away from fire and heat sources. It should be stored separately from oxidants and alkalis, and should not be mixed. Equipped with corresponding varieties and quantities of fire fighting equipment. The storage area should be equipped with suitable materials to contain leaks. | |||||||

| Transportation | It should be fireproof, moisture-proof, and anti-static during transportation. When handling bagged products, they should be lightly loaded and unloaded to prevent packaging damage | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Terephthalic acid (PTA), Industrial fine terephthalic acid | |||||||

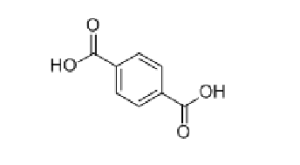

| Structure |  C8H6O4 C8H6O4 |

|||||||

| CAS No. | 100-21-0 | Boiling Point (℃) | 392.4ºC at 760 mmHg | |||||

| Molecular Weight | 166.13100 | Melting Point (℃) | 300 °C | |||||

| Appearance | White crystal or powder | Density | 1,51 g/cm3 | |||||

| HS Code | 2917361100 | Flash Point | 260°C | |||||

| Solubility | Soluble in dimethylformamide; very slightly soluble in alcohol | Vapor pressure | 1.83E-15mmHg at 25°C | |||||

| Safety Phrases | S26-S36 | ||

| RIDADR | NONH for all modes of transport | ||

| WGK Germany | 3 | ||

| Packaging Group | N/A | ||

| Hazard Codes | Xi | ||

| FIRST AID | |

| Inhalation | Leave the scene to a place with fresh air. Seek medical attention. |

| Skin | Remove contaminated clothing and rinse with flowing water |

| Eyes | Immediately open the upper and lower eyelids and rinse with flowing water for 15 minutes. Seek medical attention. |

| Ingestion | Those who take it by mistake gargle their mouths, drink milk or egg white, and seek medical attention. |

Frequently Asked Questions

What is PTA Purified Terephthalic Acid ?

PTA, which stands for Purified Terephthalic Acid, is a chemical compound that plays a crucial role in the production of polyester. It is a white, crystalline powder with a chemical formula of C₆H₄(CO₂H)₂. PTA is primarily used as a raw material in the manufacture of polyethylene terephthalate (PET), a versatile thermoplastic polymer.

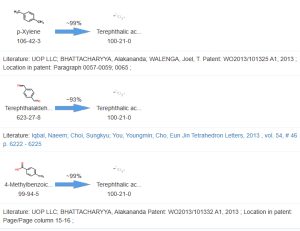

The production of PTA involves the oxidation of para-xylene, a hydrocarbon derived from petroleum or natural gas. The process typically includes several steps, such as oxidation, purification, and crystallization, to obtain high-purity PTA. The impurities are removed to ensure the quality and consistency of the final product.

PET, which is synthesized from PTA and ethylene glycol, has various applications. It is widely used in the production of polyester fibers, polyester films, and PET bottles for packaging beverages, food, and other consumer products. PTA is a key component in the polyester industry and contributes significantly to the production of a range of everyday items.

Uses of Terephthalic Acid

Terephthalic acid (TPA) is a key chemical compound primarily used in the production of polyethylene terephthalate (PET) resin, which is widely used in various applications. Here are some of the main uses of terephthalic acid:

1. PET Resin: The primary application of terephthalic acid is in the production of PET resin. PET resin is used to manufacture a wide range of products, including beverage bottles, food containers, polyester fibers for clothing and textiles, plastic films, and packaging materials.

2. Synthetic Fibers: Terephthalic acid is an essential component in the production of synthetic fibers like polyester. Polyester fibers are used in the textile industry to make clothing, upholstery, carpets, and other fabric-based products.

3. Packaging Materials: PET resin derived from terephthalic acid is commonly used for packaging materials due to its excellent barrier properties, transparency, and strength. It is extensively used for the production of bottles, jars, and containers for beverages, food, personal care products, and household items.

4. Films and Sheets: Terephthalic acid-based PET films are widely used in the packaging industry. These films provide a protective barrier, good tensile strength, and clarity, making them suitable for applications like food packaging, labels, lamination, and insulation.

5. Engineering Plastics: Terephthalic acid can be used as a building block to produce various engineering plastics. These plastics exhibit good mechanical properties, chemical resistance, and thermal stability, making them suitable for applications such as automotive parts, electrical components, and industrial equipment.

6. Coatings: Terephthalic acid can be used in the production of coatings and paints. These coatings offer durability, weather resistance, and glossy finishes. They are used in the automotive industry, appliances, furniture, and other applications that require protective and decorative coatings.

7. Adhesives: Terephthalic acid-based polymers can be used in the formulation of adhesives, providing strong bonding properties for various substrates.

8. Dye Intermediates: Terephthalic acid is a precursor for the production of various dyes and pigments. It is used in the synthesis of colorants for textiles, plastics, and other materials.

It’s worth noting that terephthalic acid is also used as a chemical intermediate in the synthesis of other compounds and as a raw material for the production of other derivatives used in various applications.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.