Industrial 1,3 butadiene

Specifications

| Item | Index | |||

| Superior product | First class product | |||

| Appearance | Colorless, transparent, no suspended matter | |||

| 1,3-butadiene,% (mass fraction) ≥ | 99.3 | 98.0 | ||

| Total alkyne, 10-6 ≤ Among them, vinyl acetylene, 10-6 ≤ | 50 5 | 100 — | ||

| Butadiene dimer (based on 4-vinyl cyclohexene), 10-6 ≤ | 1000 | 1000 | ||

| Carbonyl compound (in terms of acetaldehyde), 10-6 ≤ | 10 | 20 | ||

| Water content, 10-6≤ | 20 | 500 | ||

| Polymerization inhibitor (TBC), 10-6 | 50~150 | 50~150 | ||

| Peroxide (in terms of H2O2), 10–6 ≤ | 10 | 10 | ||

| Oxygen content of the gas phase, % (volume fraction) ≤ | 0.3 | 0.3 | ||

Packing & Storage

| Packing | 200kg/barrel | |||||||

| Storage | Store in a cool and ventilated special warehouse for flammable gases. Keep away from fire and heat sources. The storage temperature should not exceed 30℃. | |||||||

| Transportation | ||||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Industrial butadiene,1,3-BUTADIENE,butadiene | |||||||

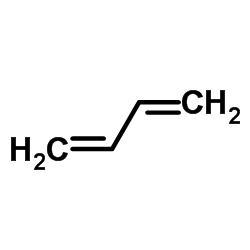

| Structure |  C4H6 C4H6 | |||||||

| CAS No. | 106-99-0 | Boiling Point (℃) | -4.4±0.0 °C at 760 mmHg | |||||

| Molecular Weight | 54.090 | Melting Point (℃) | −109 °C(lit.) | |||||

| Appearance | A colorless gas, with a special odor, has anesthetic and stimulating effects and is easy to liquefy | Density | 0.6±0.1 g/cm3 | |||||

| Vapour density | 1.9 (15 °C, vs air) | Flash Point | -76.1±0.0 °C | |||||

| Solubility | Soluble in most organic solvents such as acetone, benzene, acetic acid, esters, etc. | Vapor pressure | 2101.8±0.0 mmHg at 25°C | |||||

| Safety Phrases | S53-S45-S62-S46-S36/37-S26-S61-S33-S16 | ||

| RIDADR | UN 1010 2.1 | ||

| WGK Germany | 2 | ||

| Packaging Group | N/A | ||

| Hazard Class | 2.1 | ||

| FIRST AID | |

| Inhalation | Don’t delay time and move the victim to fresh air. If the victim cannot return to normal quickly, he or she must be transferred to the nearest medical institution for further treatment. |

| Skin | Take off the contaminated clothing and immediately rinse the contaminated skin with plenty of water for at least 15 minutes, and then wash with soap if possible. If there is redness, swelling, pain, or blisters, transfer to the nearest medical institution for further treatment. |

| Eyes | Immediately rinse your eyes with plenty of water, while keeping your eyelids open, rinse for at least 15 minutes. Seek medical attention nearby. |

| Ingestion | Do not induce vomiting.Immediately take them to the nearest medical facility for further treatment.If spontaneous vomiting occurs, keep your head low and your legs high to prevent vomit from entering the respiratory tract. |

Frequently Asked Questions

Applications of Industrial 1,3 butadiene

Industrial 1,3-butadiene, also known as butadiene or BD, is a versatile chemical compound with various applications in different industries. Here are some common applications of industrial 1,3-butadiene:

1. Synthetic Rubber: One of the primary uses of 1,3-butadiene is as a raw material for the production of synthetic rubber, particularly styrene-butadiene rubber (SBR) and polybutadiene rubber (BR). These rubbers have excellent resilience, abrasion resistance, and low-temperature flexibility, making them suitable for the manufacture of tires, conveyor belts, hoses, gaskets, and various other rubber products.

2. Polymer Manufacturing: 1,3-Butadiene is a crucial monomer used in the production of several polymers, including acrylonitrile-butadiene-styrene (ABS), styrene-butadiene latex (SBL), and polybutadiene. ABS is a tough and impact-resistant plastic used in automotive parts, electronic appliances, and toys. SBL is used in adhesives, coatings, and paper finishes. Polybutadiene finds applications in the production of golf ball cores, footwear soles, and other molded rubber products.

3. Chemical Intermediates: 1,3-Butadiene serves as a starting material for the synthesis of various chemical intermediates. It can be used to produce adiponitrile, a key precursor in the production of nylon-6,6, a high-performance engineering plastic. Additionally, it is used to manufacture maleic anhydride, which is utilized in the production of resins, coatings, and other chemicals.

4. Fuel and Energy Applications: In some cases, 1,3-butadiene can be utilized as a fuel additive or as a source of energy. It can be blended with gasoline to increase its octane rating and improve combustion efficiency. Furthermore, butadiene can undergo steam cracking to produce valuable chemicals and feedstocks for the petrochemical industry, such as ethylene and propylene.

5. Pharmaceuticals: 1,3-Butadiene derivatives have found applications in the pharmaceutical industry. Some pharmaceutical compounds, such as antimalarial drugs and antiviral agents, contain butadiene-derived moieties that contribute to their therapeutic properties.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.