Ashless dispersant

Specifications

| Item | Index | Experimental method | |||

| T151 | T154A | T161 | |||

| Appearance | Brown-red viscous transparent liquid | Visual inspection | |||

| Density (20℃), kg/m3 | 890-930 | 890-935 | 910-935 | GB/T1884 | |

| Kinematic viscosity (100℃), mm2/s | 130-250 | 70-150 | 300-500 | GB/T 265 | |

| Total alkali value mg KOH/g | 40-70 | 15~30 | 20-30 | SH/T 0251 | |

| Nitrogen content,% | ≥2 | 1.1-1.3 | 1.0-1.3 | SH/T 0224 | |

| Chromaticity (dilution) ≤ | 3.0 | 3.0 | 3.0 | GB/T 6540 | |

| Mechanical impurities, % ≤ | 0.08 | 0.08 | 0.08 | GB/T 511 | |

| Flash point (opening), ℃≥ | 180 | 180 | 180 | GB/T 267 | |

| Moisture,%≤ | 0.08 | 0.08 | 0.08 | GB/T 260 | |

| Dispersion SDT≥ | 55 | 55 | 60 | SH/T 0623 | |

Packing & Storage

| Packing | 200 liters standard iron drum, the net weight of the product is 170Kg/barrel; tank car in bulk. | |||||||

| Storage | The maximum storage temperature should not exceed 75℃; if stored for a long time, the maximum temperature should not exceed 45℃. For product safety, user health, and environmental precautions, please refer to the relevant chemical safety data sheet. | |||||||

| Transportation | When storing, transporting, loading, unloading, and oil transfer of this product refer to SH/T0164. This product is not flammable, non-explosive, or non-corrosive. | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Ashless Dispersant | |||||||

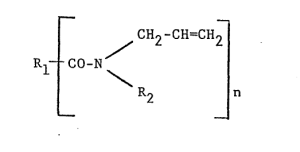

| Structure |  | |||||||

| CAS No. | N/A | Boiling Point (℃) | N/A | |||||

| Molecular Weight | N/A | Melting Point (℃) | N/A | |||||

| Appearance | N/A | Density | N/A | |||||

| HS Code | N/A | Flash Point | 180 | |||||

| Solubility | N/A | Vapor pressure | N/A | |||||

| Safety Phrases | N/A | ||

| RIDADR | N/A | ||

| WGK Germany | N/A | ||

| Packaging Group | N/A | ||

| Hazard Class | N/A | ||

| FIRST AID | |

| Inhalation | N/A |

| Skin | N/A |

| Eyes | N/A |

| Ingestion | N/A |

1. a preparation method for boronation ashless dispersant, comprises the steps: First, aminated compounds and epoxy propanol are carried out the ring-opening reaction and prepare middle product amine; Then, polyisobutylene maleic anhydride and base oil are reacted with the above-mentioned middle product amine, prepares Polyisobutene succinimide;

Frequently Asked Questions

Since the 1960s, ashless dispersants have been used in lubricating oils and fuel oils. The use of ashless dispersants can solve the problem of sludge, so as to ensure the normal operation of locomotives.There are many types of ashless dispersants, and polyisobutylene ashless dispersants mainly include polyisobutylene succinimide, polyisobutylene bissuccinimide, polyisobutylene polysuccinimide, high molecular weight ashless dispersant, boron modified ashless dispersant, polyisobutylene succinate, polyisobutylene ashless phosphate, and other varieties.

Currently, polyamine based succinimide is the mainstream product of dispersants, accounting for over 80% of the total amount of dispersants used. The chemical structure is composed of an lipophilic group, a polar group, and a connecting part. This chemical structure is extremely easy to form micelles in lubricating oil, ensuring that it has a strong solubilizing effect on the initial oxidation products of the liquid state, and has a good gel solubility and dispersion effect on solid particles such as carbon deposits and soot, effectively ensuring the low-temperature dispersion performance of internal combustion engine oil, especially effectively solving the low-temperature sludge problem of gasoline engine oil. When gasoline engine oil with dispersant is changed after running for a long time, the amount of oil sludge in the crankcase decreases, and it also improves the dispersion and solubilization of soot and oxidation products of lubricating oil generated by high-temperature oxidation. Especially when combined with metal detergents, it has a synergistic effect, which not only improves the quality of lubricating oil, but also reduces the amount of additives added. Due to its advantages in this field, succinimide ashless dispersants have obtained rapid development and application.

As the main function of dispersants in oil products is dispersion and solubilization, in modern automotive engine oils, the smoke point of automotive diesel oil can be effectively controlled by adding 1-10% of dispersants. Railway locomotive oil requires good alkali storage and high dispersion performance, and dispersants are also required; For medium speed cylindrical piston engine oils, it is preferred to use a smaller dosage of 2-4% to achieve dispersion performance; Generally, dispersants are not used in traditional production of marine cylinder oil, but laboratory research has found that adding dispersants can not only improve the detergency and dispersion of marine cylinder oil, but also greatly reduce the amount of highly alkaline additives added and reduce costs. At present, dispersants are also increasingly used in the production of marine cylinder oil. Two-stroke gasoline engine oil is a mixture of lubricating oil and fuel oil for combustion. Excessive metal detergents and antioxidants can easily cause wear and ring adhesion. The use of special dispersants or detergents in combination can prevent this phenomenon. In addition, it should be pointed out that due to the presence of low molecular weight polyisobutylene alkyl groups in succinimide type dispersants, adding too much will increase the low-temperature viscosity, which is inconvenient for configuring multi-level oils. For example, adding polymerizable dispersants (viscosity index improvers) instead of some dispersants can improve low-temperature performance and provide sufficient low-temperature dispersion.

What are the effects of dispersants?

Solubilization

Some oxidation products are polymerized and mixed with condensed water to form engine sludge, which increases carbon deposits in the engine and adheres to the fuel tank to prevent the suction of the oil pump, thereby clogging the filter screen. The succinimide dispersant can form micelles with oil-insoluble carbon deposits and oil sludge, and complex with them to form an oil-soluble liquid and disperse in oil. The dispersant has the best solubilization effect, which is about 10 times higher than that of the detergent.

Dispersion

The oil-soluble group provided by the dispersant is larger than that of the detergent, which can effectively block the mutual aggregation of carbon deposits and colloids, and can effectively disperse particles of 0~100nm in the oil.

With the improvement of environmental protection requirements and application standards, higher and higher requirements have been put forward for the production of ashless dispersant products. Firstly, its viscosity growth at low temperatures should be as small as possible; Secondly, it can effectively maintain high-temperature viscosity; Good compatibility with other additives; Good water resistance; Good sealing performance to rubber, as well as no damage to the environment and workers during the preparation process. Therefore, polyisobutylene ashless dispersants will develop towards functionalization such as high molecular weight, excellent oil sludge dispersion performance, high stability, and wear resistance, while the synthesis of polyisobutylene succinimide will develop towards low pollution such as thermal addition and catalytic addition.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.