Polypropylene Resin QP81N (PP QP81N)

Specifications

| Technical Item | Superior quality | Qualified product | Experiment method |

| Cleanliness, color g/kg | ≤ 10 | ≤ 15 | SH/T 1541-2006 |

| Large and small grains | ≤ 10 | ≤ 10 | SH/T 1541-2006 |

| MFR,g/10min | 20.0~30.0 | 20.0~30.0 | GB/T 3682-2000 |

| Tensile Yield Strength Mpa | ≥ 19.0 | ≥ 19.0 | ASIMD 638-03 |

| Notched Izodimpact Strength-20℃KJ/m2 | ≥ 6.0 | ≥ 5.5 | GB/T 1843-1996 |

| Flexural Modulus MPa | ≥700 | ≥700 | GB/T 9341-2000 |

Packing & Storage

| Packing | Packed in polypropylene woven bag with inner coating, the net content of each bag is 25kg. | |||||||

| Storage | Polypropylene resin should be stored in a ventilated, dry, clean, and well-maintained warehouse with good fire-fighting facilities. When storing, keep away from heat sources and prevent direct sunlight. It is strictly forbidden to store in the open air. | |||||||

| Transportation | Sharp tools such as iron hooks are prohibited during transportation, loading, and unloading. During transportation should be kept clean, dry, and equipped with compartments or clothes. It shall not be mixed with sand, broken metal, coal, glass, etc. during transportation. | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Polypropylene Resin QP81N, PP QP81N | |||||||

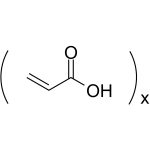

| Structure |  (C3H4O2)x (C3H4O2)x | |||||||

| CAS No. | 9003-01-4 | Boiling Point (℃) | 116ºC | |||||

| Molecular Weight | 2000(Average) | Melting Point (℃) | 106ºC | |||||

| Appearance | White Powder | Density | 1.09 (30% aq.) | |||||

| HS Code | 3906909090 | Flash Point (ºF) | 61.6ºC | |||||

| Solubility | Easily soluble in various organic solvents | LogP | 0.25700 | |||||

| Safety Phrases | S24/25 | ||

| RIDADR | UN 3265 8/PG 3 | ||

| WGK Germany | 3 | ||

| Hazard Codes | C: Corrosive;T: Toxic;Xi: Irritant; | ||

| RTECS | AT4680000 | ||

| FIRST AID | |

| Inhalation | If inhaled, move the patient to fresh air. If breathing stops, perform artificial respiration. Consult a doctor. |

| Skin | If inhaled, move the patient to fresh air. If breathing stops, perform artificial respiration. Consult a doctor. |

| Eyes | Rinse thoroughly with plenty of water for at least 15 minutes and consult a doctor. |

| Ingestion | Never feed anything through the mouth to the unconscious person. Rinse your mouth with water. Consult a doctor.Consult a doctor. |

The industrial synthesis methods of PP resin include solution, bulk, and gas phase. The propyl terminal with more than 99% purity is often used as raw material. In the alkyl warp (burned, heptane realm): TOL and (CH5) 2AICI are used as catalysts, hydrogen is the relative molecular mass regulator, and coordination polymerization is carried out at 50C and 1MPa pressure.

Frequently Asked Questions

Polypropylene Resin QP81N, commonly called PP QP81N, is a polypropylene (PP) resin used in various manufacturing processes. PP is a thermoplastic polymer that belongs to the polyolefin family and is widely used in many applications due to its excellent combination of properties.

PP QP81N is designed to provide high-impact resistance, good stiffness, and excellent processability. It is often used in injection molding processes to produce various products, including automotive parts, household appliances, packaging materials, and consumer goods.

Here are some key characteristics and properties of PP QP81N:

1. High Impact Resistance: PP QP81N exhibits excellent impact resistance, making it suitable for applications that require durability and toughness.

2. Stiffness: It offers good stiffness, providing structural integrity to molded parts.

3. Processability: PP QP81N has good melt flow properties, allowing easy processing and high productivity in injection molding operations.

4. Chemical Resistance: Polypropylene, in general, has good chemical resistance, and PP QP81N is no exception. It can withstand exposure to various chemicals and solvents, making it suitable for applications in the chemical industry.

5. Heat Resistance: PP QP81N has a relatively high melting point compared to other thermoplastics, which gives it good heat resistance. It can withstand elevated temperatures without significant deformation.

6. Electrical Insulation: PP QP81N exhibits excellent electrical insulation properties, making it suitable for electrical and electronic applications.

It’s important to note that the specific properties and characteristics of PP QP81N can vary depending on the manufacturer and the grade of the resin. Therefore, it’s recommended to refer to the technical datasheet provided by the manufacturer for detailed information about the material’s properties, processing guidelines, and application suitability.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.