Industrial glacial acetic acid

Specifications

| Item | Index | |||||

| Supperior product | First class product | Quality product | ||||

| Chromaticity, Hazen unit (platinum-cobalt color number)≤ | 10 | 20 | 30 | |||

| Acetic acid content,%≥ | 99.8 | 99.0 | 98.0 | |||

| Moisture,%≤ | 0.15 | — | — | |||

| Formic acid content,%≤ | 0.06 | 0.15 | 0.35 | |||

| Acetaldehyde content,%≤ | 0.05 | 0.05 | 0.10 | |||

| Evaporation residue,%≤ | 0.01 | 0.02 | 0.03 | |||

| Iron content (in terms of Fe),% ≤ | 0.00004 | 0.0002 | 0.0004 | |||

| Reduced potassium permanganate substance, min ≥ | 30 | 5 | — | |||

Packing & Storage

| Packing | Steel gas cylinders; ordinary wooden boxes outside ampoules; ordinary wooden boxes outside threaded glass bottles, pressed glass bottles with iron caps, plastic bottles or metal barrels (cans); tankers (filling coefficient 0.626 tons /cubic meter). | |||||||

| Storage | Store in a cool and ventilated warehouse. Keep away from fire and heat sources. The storage temperature should be kept higher than 16℃ during the freezing season to prevent solidification. Keep the container sealed. | |||||||

| Transportation | The railway transportation time limit of this product is shipped by an aluminum-made enterprise’s tanker, and it must be reported to the relevant departments for approval before shipment. The packaging should be complete at the time of shipment and the loading should be safe. During road transportation, follow the prescribed route and do not stop in residential areas and densely populated areas. | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Industrial glacial acetic acid, Acetic acid glacial, acetic acid | |||||||

| Structure | C2H4O2 | |||||||

| CAS No. | 64-19-7 | Boiling Point (℃) | 117.1±3.0 °C at 760 mmHg | |||||

| Molecular Weight | 60.052 | Melting Point (℃) | 16.2 °C(lit.) | |||||

| Appearance | Colorless transparent liquid | Density | 1.1±0.1 g/cm3 | |||||

| HS Code | 29152100 | Flash Point | 40.0±0.0 °C | |||||

| Solubility | Soluble in water, ether, glycerin, insoluble in carbon disulfide. | Vapor pressure | 13.9±0.2 mmHg at 25°C | |||||

| Safety Phrases | S26-S36/37/39-S45-S23-S24/25 | ||

| RIDADR | UN 1792 8/PG 2 | ||

| WGK Germany | 3 | ||

| Packaging Group | II | ||

| Hazard Class | 8 | ||

| FIRST AID | |

| Inhalation | Don’t delay time and move the victim to fresh air. If the victim cannot return to normal quickly, he or she must be transferred to the nearest medical institution for further treatment. |

| Skin | Take off the contaminated clothing and immediately rinse the contaminated skin with plenty of water for at least 15 minutes, and then wash with soap if possible. If there is redness, swelling, pain, or blisters, transfer to the nearest medical institution for further treatment. |

| Eyes | Immediately rinse your eyes with plenty of water, while keeping your eyelids open, rinse for at least 15 minutes. Seek medical attention nearby. |

| Ingestion | Do not induce vomiting.Immediately take them to the nearest medical facility for further treatment.If spontaneous vomiting occurs, keep your head low and your legs high to prevent vomit from entering the respiratory tract. |

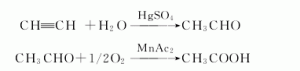

Acetylene method: Acetylene and water are directly hydrated in the presence of a catalyst to obtain acetaldehyde, and then acetaldehyde is oxidized with oxygen in the acetic acid solution of a manganese acetate catalyst.

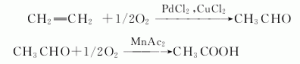

Ethylene method: Ethylene and oxygen are directly oxidized in the presence of a catalyst to synthesize acetaldehyde in one step, and then acetic acid is obtained by oxidation.Light oil liquid phase oxidation method: The light oil is oxidized in the liquid phase in the presence of a cobalt catalyst to produce a mixture of acetic acid, formic acid, propionic acid, butyric acid, etc., and then distilled twice to obtain it.

Frequently Asked Questions

What is Industrial Glacial Acetic Acid?

Vinegar is a condiment we use in our lives, and its raw material is glacial acetic acid. Acetic acid is also used in industry, called industrial glacial acetic acid, industrial glacial acetic acid cannot be eaten as ordinary vinegar.

Industrial glacial acetic acid is a colorless transparent liquid with a pungent odor. It is soluble in water, ethanol and ether. Anhydrous acetic acid solidifies into ice at low temperature, commonly known as glacial acetic acid. Volume expansion during solidification may cause container rupture. The flash point is 39°C, the explosion limit is 4.0%~16.0%, and the maximum allowable concentration in the air is not more than 25mg/m3.

What is the use of industrial glacial acetic acid?

Glacial acetic acid occupies an important position in organic chemical industry and is one of the important organic chemical raw materials. Acetic acid is widely used in synthetic fibers, coatings, medicine, pesticides, food additives, dyeing and weaving and other industries, and is an important part of the national economy.

Glacial acetic acid is one of the most important organic acids, mainly used in vinyl acetate, acetic anhydride, cellulose acetate, cellulose acetate and metal acetate. It is also used as solvent and raw material in pesticide, medicine, dyestuff and other industries, and is widely used in photography, medicine manufacturing, fabric printing and dyeing and rubber industry.

The concentrations of glacial acetic acid for washing were 28%, 56% and 99%, respectively. If you buy glacial acetic acid, add 28ml of glacial acetic acid to 72ml of water to get 28% acetic acid. More commonly, it is sold at a strength of 56%, since this strength of acetic acid requires only the addition of an equal amount of water to obtain 28% acetic acid. When the concentration of acetic acid is high, 28% acetic acid can damage acetate and dinar fibers.

Industrial glacial acetic acid is mainly used in chemical industry and manufacturing industry, and industrial glacial acetic acid is prohibited from being used in food. Industrial glacial acetic acid is corrosive to the human body and harmful because it contains a large amount of impurities, heavy metals and benzene.

Industrial glacial acetic acid is primarily used in various industrial applications, including:

1. Chemical Manufacturing: It serves as a vital raw material for the production of numerous chemicals, such as vinyl acetate monomer (VAM), acetic anhydride, esters, cellulose acetate, and more.

2. Solvent: Glacial acetic acid can act as a solvent for different organic compounds, making it useful in various industries like pharmaceuticals, dyes, and inks.

3. Textile Industry: It is used for dyeing and finishing processes in the textile industry.

4. Food Industry: Although not as common as its diluted form (vinegar), glacial acetic acid can be used in food processing as an acidity regulator and preservative. However, it is crucial to handle it with caution due to its high concentration.

5. Laboratory Use: Glacial acetic acid finds applications in laboratories as a reagent, especially in analytical chemistry and organic synthesis.

It’s important to note that glacial acetic acid is highly corrosive and can cause severe burns, so it should be handled with care and appropriate safety precautions. Proper ventilation and personal protective equipment (PPE) should be used when working with this concentrated form of acetic acid.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.