Industrial ethylene oxide

Specifications

| Item | Index | |

| Appearance | Colorless liquid | |

| Purity, wt% | >99 | |

| C9 aromatics and light components, wt% | <0.15 | |

| Other C10 alkylbenzene, wt% | balance | |

| C11 aromatics and recombinant points, wt% | <0.2 | |

| Bromine index, mgBr/100g | <5 | |

| Carbonyl base, mg/L | <1 | |

| Total sulfur, µg/g | <1 | |

| Total nitrogen, µg/g | <1 | |

| Total chlorine, µg/g | <1 | |

| Chromaticity (Pt-Co) | <10 | |

| Density 20℃, g/ml | 0.865±0.005 | |

Packing & Storage

| Packing | Steel gas cylinders; ordinary wooden boxes outside ampoules. | |||||||

| Storage | Store in a cool and ventilated warehouse.Keep away from fire and heat sources.Avoid light.The storage temperature should not exceed 30℃.It should be stored separately from acids, alkalis, alcohols, and edible chemicals, and should not be mixed.Explosion-proof lighting and ventilation facilities are adopted.It is forbidden to use mechanical equipment and tools that are prone to sparks. | |||||||

| Transportation | When using steel cylinders for transportation, you must wear a helmet on the cylinder.The steel cylinder is generally placed flat, and the mouth of the bottle should be in the same direction, and it should not be crossed; the height shall not exceed the protective fence of the vehicle, and it should be firmly clamped with triangular wooden pads to prevent rolling.During transportation, the transportation vehicle should be equipped with corresponding varieties and quantities of fire-fighting equipment | |||||||

Free Quote

At present, the company has more than 10 advanced production lines of the hollow glass microspheres with the annual production capacity of 15 thousand tons. To meet the demand of customers, the company can expand production capacity as soon as possible within 20 days. 6S principles Implemented in the production systems.

For samples, pricing, or more information, please call us at 0086 25 51192301 or mail to info@ascent-chem.com or fill out the following form. We will respond to you as soon as possible.

Tel: 0086 25 51192301

E-mail: info@ascent-chem.com

General Information

| Common Names | Industrial ethylene oxide, Oxirane | |||||||

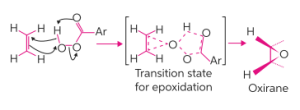

| Structure |  C2H4O C2H4O | |||||||

| CAS No. | 75-21-8 | Boiling Point (℃) | 10.7 °C(lit.) | |||||

| Molecular Weight | 44.0526 | Melting Point (℃) | −111 °C(lit.) | |||||

| Appearance | Colorless gas with characteristic odor | Density | 0.882 g/mL at 25 °C(lit.) | |||||

| HS code | 2910100000 | Flash Point | —17.7ºC | |||||

| Solubility | Soluble in water, most organic solvents | Autoignition Temperature | 804 °F (429 °C) | |||||

| Safety Phrases | S53-S45-S36/37-S16-S24/25-S23 | ||

| RIDADR | UN 2037 2.3 | ||

| WGK Germany | 2 | ||

| RTECS | KX2450000 | ||

| Hazard Class | 2.3 | ||

| FIRST AID | |

| Inhalation | Don’t delay time and move the victim to fresh air. If the victim cannot return to normal quickly, he or she must be transferred to the nearest medical institution for further treatment. |

| Skin | Take off the contaminated clothing and immediately rinse the contaminated skin with plenty of water for at least 15 minutes, and then wash with soap if possible. If there is redness, swelling, pain, or blisters, transfer to the nearest medical institution for further treatment. |

| Eyes | Immediately rinse your eyes with plenty of water, while keeping your eyelids open, rinse for at least 15 minutes. Seek medical attention nearby. |

| Ingestion | Do not induce vomiting.Immediately take them to the nearest medical facility for further treatment.If spontaneous vomiting occurs, keep your head low and your legs high to prevent vomit from entering the respiratory tract. |

Frequently Asked Questions

Applications of Industrial ethylene oxide

Industrial ethylene oxide (EO) is a versatile chemical compound with various applications across different industries. Some of the key applications of industrial ethylene oxide are:

1. Ethylene Glycol Production: Ethylene oxide is primarily used in the production of ethylene glycol, which is a key component in the manufacturing of polyester fibers, polyethylene terephthalate (PET) resins used in bottles and packaging, antifreeze, and other industrial products.

2. Surfactants and Emulsifiers: Ethylene oxide is used as a key building block in the production of surfactants and emulsifiers. These substances are widely employed in the manufacturing of personal care products, detergents, cleaning agents, and cosmetics. Ethoxylated surfactants are valued for their ability to improve the solubility and stability of formulations.

3. Ethanolamines: Ethylene oxide is used in the production of ethanolamines, such as monoethanolamine (MEA), diethanolamine (DEA), and triethanolamine (TEA). Ethanolamines are used as intermediates in the production of various chemicals, including detergents, herbicides, corrosion inhibitors, and pharmaceuticals.

4. Glycol Ethers: Ethylene oxide reacts with alcohols to produce glycol ethers, which find applications as solvents in industries such as paints, coatings, inks, and cleaning products. Glycol ethers offer good solvency properties and are valued for their ability to dissolve various substances effectively.

5. Polyols for Polyurethane Production: Ethylene oxide is used to produce polyols, which are essential building blocks for the production of polyurethane foams, elastomers, coatings, adhesives, and sealants. Polyurethanes are widely used in industries such as construction, automotive, furniture, and bedding.

6. Pharmaceuticals: Ethylene oxide is utilized in the sterilization of medical equipment and devices, including surgical instruments, syringes, catheters, and bandages. It is an effective method for eliminating bacteria, viruses, and other microorganisms, ensuring the safety and sterility of medical products.

7. Pesticides and Herbicides: Ethylene oxide is used as an intermediate in the production of certain pesticides and herbicides. It helps in the synthesis of active ingredients and formulations used in agricultural applications to protect crops from pests and weeds.

It’s important to note that while industrial ethylene oxide has several valuable applications, it is also a hazardous substance and requires careful handling and storage due to its flammability and potential health risks. Strict safety measures and regulations are in place to ensure its safe use in industrial processes.

Contact Us

TEL: 0086 25 51192301

EMAIL: info@ascent-chem.com

EMAIL: sophiahoney247@gmail.com

Copyright © Ascent Sbr All Rights Reserved.